February 2023

BrewSake.org BETA Site Launch

After an exhaustive search for a platform that serves our needs to organize information in a way that is both approachable and easily managed, we have launched a beta version of BrewSake.org

Since this is entirely a volunteer effort, there will be some construction dust here and there. If you think you can donate your time to write up a small section or even an entire blog post, please contact us and we’ll figure out a time to talk. You can also just send in content updates and we’ll integrate it into the site.

From a tone perspective, this might read a little more irreverent than your standard “how-to” and that is by design. Formal language always feels like there are details not being shared with you. We want to underscore the principal of knowledge sharing by remaining as casual as we can without risking credibility.

Let’s blog about Brews, Baby.

There are quite a few blogs about beer brewing and sake could definitely use some help filling in the blanks. While the main site is definitely about the brewing basics and ensuring people have a good sense of what to expect when starting down the sake brewing journey, the blog is about going deep on topics that require a lot more detail or have so many caveats it would be difficult to read for beginners.

As new content is added we’ll go back to main site (brewsake.org) and link out to these and what we’d consider peer sites that can expand upon these topics further. SakeDeepDive, Sake Revolution, SakeOnAir, and plenty of other great resources exist that can really expand the conversation, so we’re gonna do our best to link out to those where ever relevant.

The BrewSake Blog

Call for Sake Recipes

This might require more of an explanation, but suffice it to say, there really are not a lot of examples of sake recipes written down anywhere that includes all of: yeast type, rice type, koji spores, moto style and temperatures, as well as any details on additions or length of fermentation.

We think that’s crap, so we’re building a recipe list that includes as many details as possible. There are things that we have learned through discussions with other brewers and through our own experimentation that shows how necessary it is to have a baseline understanding of rice type, koji type, water ratios, and other details in order to fully grasp how different changes to a recipe will effect the final sake.

Just based on the principal of Sake Zukuri Ban Ryu (that fun idea that there are 10,000 ways to brew sake), there is no way for you to read a recipe and recreate it one-for-one, but you can have some understanding of polish rate, water ratio, yeast type, and perhaps other details that will give you a lot of perspective when it comes to designing your own.

Check out the spreadsheet linked to in the blog post and let us know what you think.

Useful Links

These are a collection of Links we pinned in the Brewers-Roundtable.

Terminology (sensory, etc)

Brewer Calls and Discord Summary

This was one heck of a month. We finally had an opportunity to speak with our fellow brewers in Europe. We troubleshooted some racking issues, researched yamahai moto, discussed water ratios and measuring fermentations on the cheap.

Same Process, Different Rice, Different Results

Bob T., who many people will know as TaylorMadeAK across the interwebs for generously posting his Yamahai recipe on several beer forums and brewing websites, was discussing a racking issue with koshihikari table rice (90%) batch. He racked the pressings into separate jugs and used bentonite to clarify them. Unlike other rice varietals he’s used, he found this one mostly remained cloudier through the racking process and only the last few liters he pressed cleared up well. The most probable assessment was that it was due to sediment building up as the batch was pressed and the final portion ran clear, but there is still some mystery surrounding the occurrence. Anyone else having clarity issues with Koshihikari table rice?

When to Change the Recipe: seimaibuai

We met a long time lurker, Mike, from Pittsburg who's been playing with Omachi and planning on using 40% seimaibuai rice. We discussed him adapting his current recipe to adjust for the new rice. Based on information shared by JJ, if you change the seimaibuai you should also change the water ratio. (source lang: JP)

I’ve included a screen shot of the basic recommendations, but suffice it to say, table rice is better at the 115-125% water ratio, so for 100kg of total rice, you would add 115 to 125 Liters of total water (split out across all your additions/moto).

Figure showing polish ratio vs water ratio recommendations.

If the water ratio is incorrect, it is possible any number of side effects could occur. If the rice melts too quickly because there isn’t enough water, the enzymes could create too much sugar, causing high osmotic pressure that will stress the yeast and could even stall the ferment or even stop it due to cell wall failure. The opposite could be true if the water is too much, which would allow the yeast to ferment quickly, and possibly finish the ferment at low alcohol and/or extremely dry.

If you are experiencing high-acidity or bitterness in your finished sake, you should consider lowering your water ratio. I’ve personally experienced this and it showed a marked improvement in the final product.

Measuring your Fermentation - Home vs Commercial Brewing

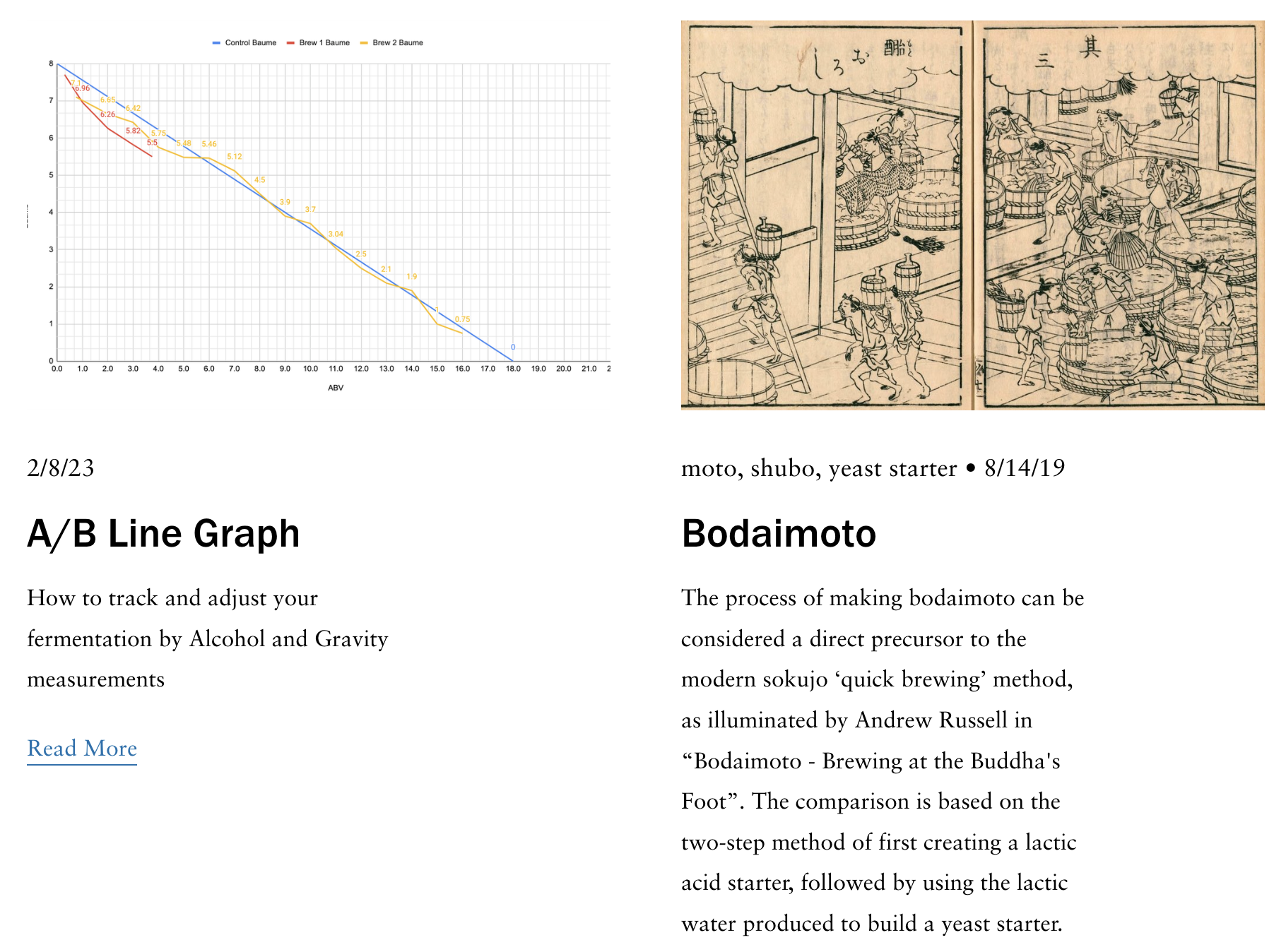

We’ve had a lot of discussion on this, especially on the A/B Line, but suffice it to say, while commercial brewers need to deliver a product within 1% ABV and therefore need a more accurate tool for measurement, the home brewers can rely on broader results. But, there are a few levels of accuracy as you go, so here’s the breakdown:

Beginner Level - mostly to get a sense of where the brew finished, but you can also use small samples (10mL of filtered sake) to measure along the way. You can use the same calculations as the Committed Home Brewer to determine ABV.

Vinometer (10-15 USD) + food coloring to measure final ABV (or anything over 10%)

Refractometer (15-40 USD) can give you a sense of brix and some even give you gravity measurements

Pycnometer + an accurate scale ( as low as 15 USD ) - can give you a relatively accurate gravity reading

Committed Home Brewer - these tools, plus a few calculations can give you a fairly accurate sense of your ABV (within 0.5% ABV margin of error)

Anton Paar EasyDens (399 USD) with only 2mL of filtered sake you can get fairly consistent and accurate gravity readings.

Atago Sake Brix and Acidity Meter (700 USD) will give you accurate Brix measurements

Commercial Brewer - I’m not even gonna touch the accuracy of the companies who are using 20,000 USD tools because that was out of the scope of our discussion, but here is the tool that will level up the ABV measurement:

Ebulliometer - (1200-5000 USD) you might be able to find these for less money, but this will allow you to accurately report your ABV as the fermentation is progressing and you can make adjustments to correct the trajectory of the A/B graph and improve consistency from batch to batch.

Microscope and Hemocytometer - For yeast counting, these will hopefully ensure you can get a little more scientific about your yeast starter so you know you have enough yeast cells to ensure a strong fermentation. This really isn’t necessary for home brewing, but it can ensure you don’t end stalling or dragging out a ferment due to a low cell count.

Yamahai Moto - Should you add Potassium Nitrate (or Calcium Nitrate)?

Home brewer Michael from Germany asked about an issue with Ethyl Acetate aromas in his Yamahai on day 7.

A few sources chimed in and threw back the following answer:

[The] koji could be kicking off alcoholic fermentation too quickly. The whole point is to really build that lactic acid before there is any alcohol produced, and then to build the yeast culture with as little alcohol production as possible.

Did this fellow add any potassium nitrate?

This kicked off a few more text messages and advice was given to add either Calcium Nitrate or Potassium Nitrate in order to ensure the water contains Nitric Acid.

A little more research discovered a post from Yusuke Sato of Arima Sake Brewery in Akita Prefecture:

In order for the nitrate-reducing bacteria to produce "nitric acid", water must have a mineral component called "nitric acid" in the first place. "Nitrite" is important to suppress the growth of wild yeast (preventing premature fermentation) until sake yeast grows . For this reason, in the case of soft water storage, minerals containing "nitric acid" are added" (source)

Closing out this discussion, Michael said:

Looking back at my graphs in Nihonshu, I am seeing that yeast should be pitched when the moto temps reach about 13 C. since my ambient temps went up a bit higher and faster than expected, I blew past that mark, probably resulting in too much alcohol production in combi with some acedic acid, thus the ethyl acetate.

Based on a side discussion in the chat, using Nitrite strips to measure the levels in the moto would also be a great way to determine when to pitch yeast, ensuring that the acid level is high enough and the yeast has a safe environment to grow.

Some kimoto and yamahai producers actually add lab produced lactobacillus to ensure less variability in the quality of the moto.

For anyone interested, here are a couple more links related to this topic:

https://www.syusendo-horiichi.co.jp/blog/4373839-2/ http://www.nommlier.jp/yamahai.htm

Pressing Issues

Separating out the initial drippings in shizuku style, or the first few liters using fune style. This allows the fine sediment to create a dense layer that will hold back additional sediment, ensuring a substantially clearer sake and will cut down on racking time and possibly even remove the need to use bentonite, biofine, or other agents to assist with settling out particles.